Drive Shaft Design Team

Shing Shing Long's R&D team consists of engineers and technicians full of experience, professional knowledge, and excellent drive shaft design capabilities. Our R&D team is not only able to design innovative drive shafts, but also to translate these designs into high-quality, high-performance products.

The vehicle drive shaft is a crucial component that influences the performance and safety of the vehicle. Therefore, the design of the drive shaft must follow specific steps and adhere to design specifications. Various principles related to how these components work together are also considered to ensure that the drive shafts we design meet the quality and specifications our customers require. When designing drive shafts, Shing Shing Long's R&D team carefully considers the following factors:

1. Drive Shaft Design

Customer specifications and product purposes, including torque requirements (such as passenger cars, trucks, off-road vehicles) based on the type of vehicles, maximum swing angle needs , and driving conditions (such as roads inside the city, off-road, climbing, water crossings, mountainous roads, and highways).

2. Material selection

Depending on the specifications and expected torque, it is necessary to determine the appropriate materials for manufacturing the drive shaft. Common materials include alloy steel and nickel-chromium steel. The choice of materials directly affects the strength, durability, and overall performance and speed of the drive shaft. In the case of racing cars, the material can influence the racing speed and performance.

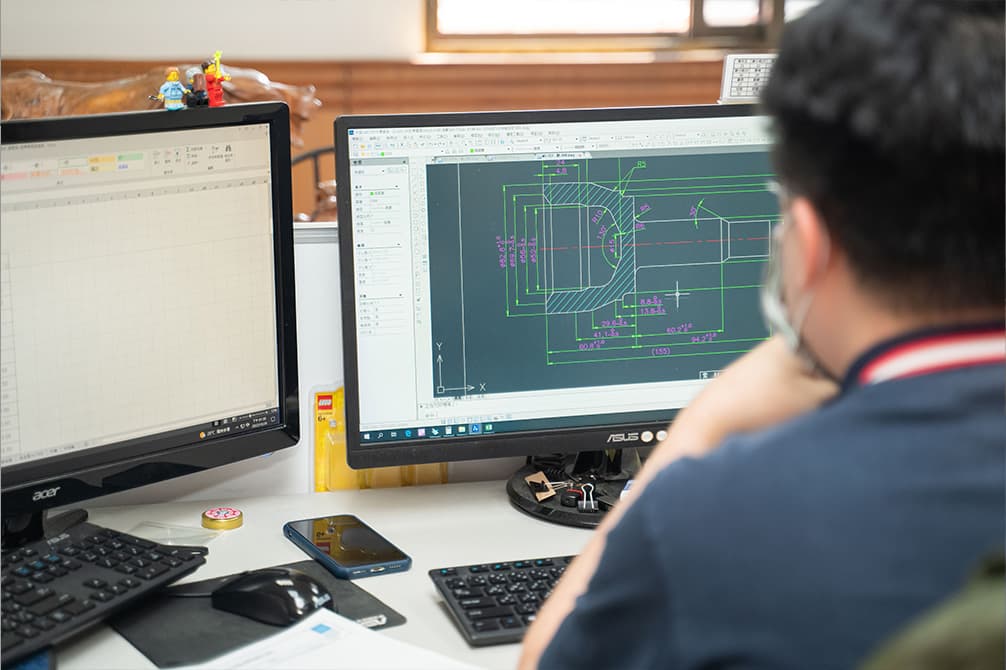

3. Design process

We use design software such as CAD and SolidWorks to enhance the efficiency and accuracy of the design process, allowing real-time design discussions with customers based on the outcome of the software.

4. Prototype production

The R&D team produces a prototype drive shaft according to the design specifications and detailed drawings. Then, a preliminary quality inspection based on actual testing helps inspect the quality and modify any emerging issues. This process also confirms the expected performance.

Our R&D team has extensive experience in drive shaft design. It can offer a variety of designs based on materials and intricacies while addressing and resolving any challenging issues for our customers. Our service commitment is to enhance customer trust, to foster long-term relationships, and to create mutually beneficial partnerships.