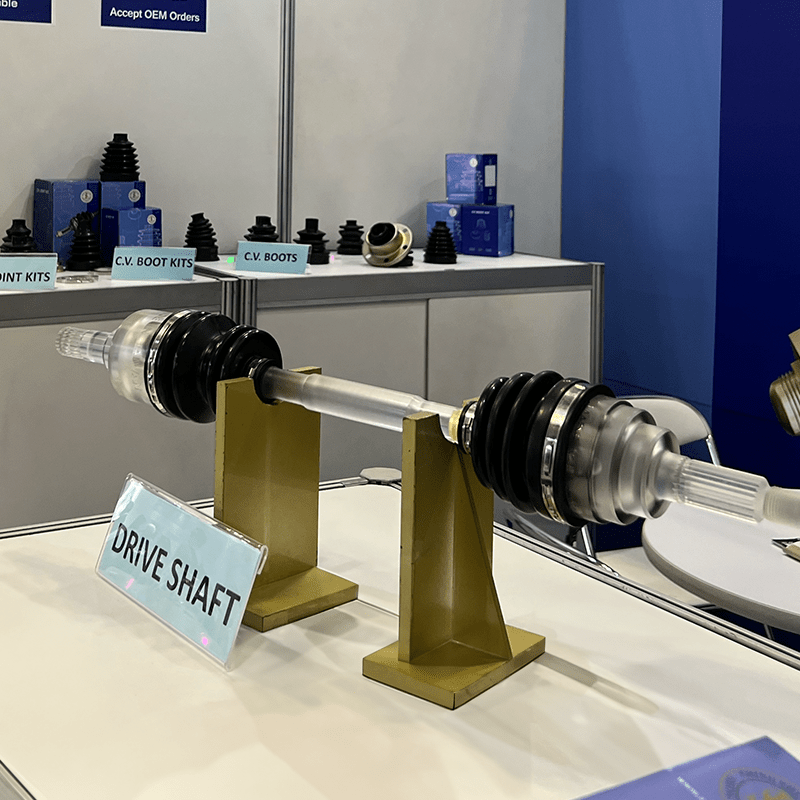

A drive shaft in a vehicle connects the transmission output shaft to the differential input shaft.

It transfers torque from the transmission to the differential, then transmits it to the wheels. A drive shaft comprises a long steel or carbon fiber tube with two universal joints that allow the shaft to flex as the car moves over uneven terrain. A flange connects the transmission and differential at each end of the drive shaft. The tube is balanced to reduce vibration and improve the vehicle's overall performance.

Several factors must be considered when manufacturing drive shafts to ensure their durability and efficiency. The material used in construction is critical, as it needs to withstand significant torque and stress while being lightweight enough not to add too much weight to the vehicle. The length and diameter of the driveshaft must also be optimized to minimize vibration and maintain the correct operation angle. Proper balancing is essential to prevent vibration and ensure smooth operation. At the same time, the design of the universal joints must allow for flexibility without sacrificing durability.

Shing Shing Long designs and manufactures drive shafts for various types of vehicles, including traditional, electric, and refitted vehicles. Contact us to discuss your drive shaft specifications!